锻钢制管件

承插焊管帽 | Socket Weld Cap

产品类型:承插焊管帽

产品规格:1/8″~4″ (DN6~DN100)

压力等级:3000#、6000#、9000#

产品材质:碳钢20#、A105;不锈钢钢F304/304L、F316/316L、F321;双相钢F51、F53、F55等

产品特点:耐腐蚀、耐高压

连接方式:焊接

产品标准:ASME 16.11、GB/T14383-2018

应用领域:海工装备、石油化工、核电工程、锅炉容器、船舶修造、热电机组、泵阀管路、燃气消防等领域.

13564974168 周经理

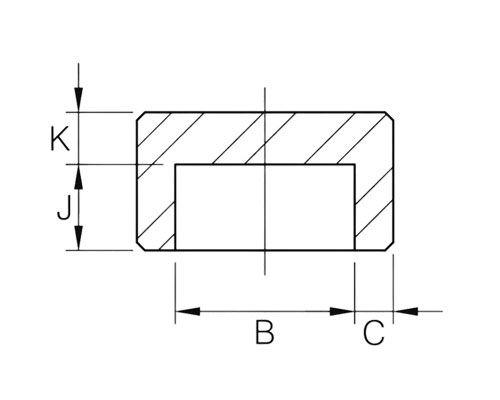

公称通径 | 承插孔径 | 承插孔壁厚 | 顶部厚度 | 承插孔深度 | ||

DN | NPS | B(2) | (Avg) | Min | K | J |

3000Lb | ||||||

6 | 1/8 | 10.8 | 3.18 | 3.18 | 4.8 | 9.5 |

8 | 1/4 | 14.2 | 3.78 | 3.3 | 4.8 | 9.5 |

10 | 3/8 | 17.6 | 4.01 | 3.5 | 4.8 | 9.5 |

15 | 1/2 | 21.8 | 4.67 | 4.09 | 6.4 | 9.5 |

20 | 3/4 | 27.2 | 4.90 | 4.27 | 6.4 | 12.5 |

25 | 1 | 33.9 | 5.69 | 4.98 | 9.6 | 12.5 |

32 | 1.1/4 | 42.7 | 6.07 | 5.28 | 9.6 | 12.5 |

40 | 1.1/2 | 48.8 | 6.35 | 5.54 | 11.2 | 12.5 |

50 | 2 | 61.2 | 6.93 | 6.04 | 12.7 | 16.0 |

65 | 2.1/2 | 73.9 | 8.76 | 7.67 | 15.7 | 16.0 |

80 | 3 | 89.8 | 9.52 | 8.30 | 19.0 | 16.0 |

100 | 4 | 115.2 | 10.69 | 9.35 | 22.4 | 19.0 |

6000Lb | ||||||

6 | 1/8 | 10.8 | 3.96 | 3.43 | 6.4 | 9.5 |

8 | 1/4 | 14.2 | 4.6 | 4.01 | 6.4 | 9.5 |

10 | 3/8 | 17.6 | 5.03 | 4.37 | 6.4 | 9.5 |

15 | 1/2 | 21.8 | 5.97 | 5.18 | 7.9 | 9.5 |

20 | 3/4 | 27.2 | 6.96 | 6.04 | 7.9 | 12.5 |

25 | 1 | 33.9 | 7.92 | 6.93 | 11.2 | 12.5 |

32 | 1.1/4 | 42.7 | 7.92 | 6.93 | 11.2 | 12.5 |

40 | 1.1/2 | 48.8 | 8.92 | 7.80 | 12.7 | 12.5 |

50 | 2 | 61.2 | 10.92 | 9.50 | 15.7 | 16.0 |

9000Lb | ||||||

15 | 1/2 | 21.8 | 9.35 | 8.18 | 11.2 | 9.5 |

20 | 3/4 | 27.2 | 9.78 | 8.56 | 12.7 | 12.5 |

25 | 1 | 33.9 | 11.38 | 9.96 | 14.2 | 12.5 |

32 | 1.1/4 | 42.7 | 12.14 | 10.62 | 14.2 | 12.5 |

40 | 1.1/2 | 48.8 | 12.70 | 11.12 | 15.7 | 12.5 |

50 | 2 | 61.2 | 13.84 | 12.12 | 19.0 | 16.0 |

备注:

(1) Average of socket Wall Thickness around periphery shall be no less than listed values.The minimum values are permitted in localized areas.插座周边的平均壁厚应不小于所列值。局部区域允许使用最小值。