锻钢制管件

渐缩管 | Swage Nipple

产品类型:渐缩管(Swage Nipple)

产品规格:1/4″~4″ (DN6~DN100)

压力等级:SCH40/STD、SCH80、SCH160、XXS

产品材质:碳钢20#、A105;不锈钢钢F304/304L、F316/316L、F321;双相钢F51、F53、F55等;

产品特点:耐腐蚀、耐高压

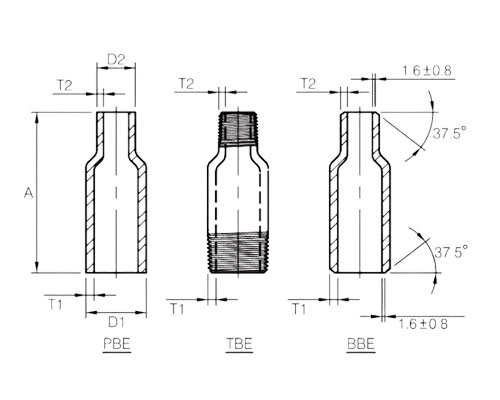

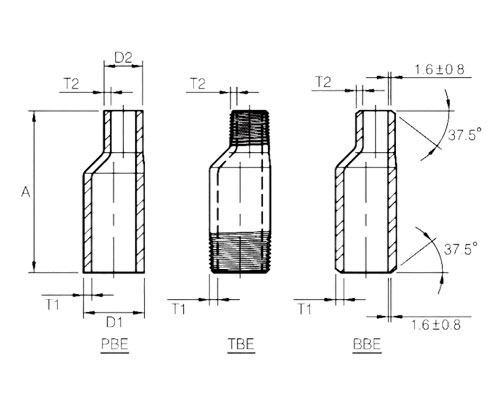

连接方式:PBE、BBE、TBE

产品标准:MSS SP-95

应用领域:海工装备、石油化工、核电工程、锅炉容器、船舶修造、热电机组、泵阀管路、燃气消防等领域.

13564974168 周经理

|

|

| 同心渐缩管结构图 | 偏心渐缩管结构图 |

Nom.Pipe Size | Outside Diameter | End to End | Wall Thickness | ||||||||

Large End D1 | Small End D2 | T1 | T2 | ||||||||

Sch40 | Sch80 | Sch160 | XXS | Sch40 | Sch80 | Sch160 | XXS | ||||

1/4X1/8 | 13.7 | 10.3 | 57 | 2.2 | 3.0 | 3.7 | 6.1 | 1.7 | 2.4 | - | - |

3/8X1/8 | 17.1 | 10.3 | 64 | 2.3 | 3.2 | 4.0 | 6.4 | 1.7 | 2.4 | - | - |

3/8X1/4 | 17.1 | 13.7 | 64 | 2.3 | 3.2 | 4.0 | 6.4 | 2.2 | 3.0 | - | - |

1/2X1/8 | 21.3 | 10.3 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 1.7 | 2.4 | - | - |

1/2X1/4 | 21.3 | 13.7 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.2 | 3.0 | - | - |

1/2X3/8 | 21.3 | 17.1 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.3 | 3.2 | - | - |

3/4X1/8 | 26.7 | 10.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 1.7 | 2.4 | - | - |

3/4X1/4 | 26.7 | 13.7 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.2 | 3.0 | - | - |

3/4X3/8 | 26.7 | 17.1 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.3 | 3.2 | - | - |

3/4X1/2 | 26.7 | 21.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.8 | 3.7 | 4.8 | 7.5 |

1X1/8 | 33.4 | 10.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 1.7 | 2.4 | - | - |

1X1/4 | 33.4 | 13.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.2 | 3.0 | - | - |

1X3/8 | 33.4 | 17.1 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.3 | 3.2 | - | - |

1X1/2 | 33.4 | 21.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.8 | 3.7 | 4.8 | 7.5 |

1X3/4 | 33.4 | 26.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.9 | 3.9 | 5.6 | 7.8 |

1.1/4X1/8 | 42.2 | 10.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 1.7 | 2.4 | - | - |

1.1/4X1/4 | 42.2 | 13.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.2 | 3.0 | - | - |

1.1/4X3/8 | 42.2 | 17.1 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.3 | 3.2 | - | - |

1.1/4X1/2 | 42.2 | 21.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.8 | 3.7 | 4.8 | 7.5 |

1.1/4X3/4 | 42.2 | 26.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.9 | 3.9 | 5.6 | 7.8 |

1.1/4X1 | 42.2 | 33.4 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 3.4 | 4.5 | 6.4 | 9.1 |

1.1/2X1/8 | 48.3 | 10.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 1.7 | 2.4 | - | - |

1.1/2X1/4 | 48.3 | 13.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.2 | 3.0 | - | - |

1.1/2X3/8 | 48.3 | 17.1 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.3 | 3.2 | - | - |

1.1/2X1/2 | 48.3 | 21.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.8 | 3.7 | 4.8 | 7.5 |

1.1/2X3/4 | 48.3 | 26.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.9 | 3.9 | 5.6 | 7.8 |

1.1/2X1 | 48.3 | 33.4 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.4 | 4.5 | 6.4 | 9.1 |

1.1/2X1.1/4 | 48.3 | 42.2 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.6 | 4.9 | 6.4 | 9.7 |

2X1/8 | 60.3 | 10.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 1.7 | 2.4 | - | - |

2X1/4 | 60.3 | 13.7 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.2 | 3.0 | - | - |

2X3/8 | 60.3 | 17.1 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.3 | 3.2 | - | - |

2X1/2 | 60.3 | 21.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.8 | 3.7 | 4.8 | 7.5 |

2X3/4 | 60.3 | 26.7 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.9 | 3.9 | 5.6 | 7.8 |

2X1 | 60.3 | 33.4 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.4 | 4.5 | 6.4 | 9.1 |

2X1.1/4 | 60.3 | 42.2 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.6 | 4.9 | 6.4 | 9.7 |

2X1.1/2 | 60.3 | 48.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.7 | 5.1 | 7.1 | 10.2 |

2.1/2X1/8 | 73.0 | 10.3 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 1.7 | 2.4 | - | - |

2.1/2X1/4 | 73.0 | 13.7 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.2 | 3.0 | - | - |

2.1/2X3/8 | 73.0 | 17.1 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.3 | 3.2 | - | - |

2.1/2X1/2 | 73.0 | 21.3 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.8 | 3.7 | 4.8 | 7.5 |

2.1/2X3/4 | 73.0 | 26.7 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.9 | 3.9 | 5.6 | 7.8 |

2.1/2X1 | 73.0 | 33.4 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.4 | 4.5 | 6.4 | 9.1 |

2.1/2X1.1/4 | 73.0 | 42.2 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.6 | 4.9 | 6.4 | 9.7 |

2.1/2X1.1/2 | 73.0 | 48.3 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.7 | 5.1 | 7.1 | 10.2 |

2.1/2X2 | 73.0 | 60.3 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.9 | 5.5 | 8.7 | 11.1 |

3X1/8 | 88.9 | 10.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 1.7 | 2.4 | - | - |

3X1/4 | 88.9 | 13.7 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.2 | 3.0 | - | - |

3X3/8 | 88.9 | 17.1 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.3 | 3.2 | - | - |

3X1/2 | 88.9 | 21.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.8 | 3.7 | 4.8 | 7.5 |

3X3/4 | 88.9 | 26.7 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.9 | 3.9 | 5.6 | 7.8 |

3X1 | 88.9 | 33.4 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.4 | 4.5 | 6.4 | 9.1 |

3X1.1/4 | 88.9 | 42.2 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.6 | 4.9 | 6.4 | 9.7 |

3X1.1/2 | 88.9 | 48.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.7 | 5.1 | 7.1 | 10.2 |

3X2 | 88.9 | 60.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.9 | 5.5 | 8.7 | 11.1 |

3X2.1/2 | 88.9 | 73.0 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 5.2 | 7.0 | 9.5 | 14.0 |

3.1/2X1/8 | 101.6 | 10.3 | 203 | 5.7 | 8.1 | - | - | 1.7 | 2.4 | - | - |

3.1/2X1/4 | 101.6 | 13.7 | 203 | 5.7 | 8.1 | - | - | 2.2 | 3.0 | - | - |

3.1/2X3/8 | 101.6 | 17.1 | 203 | 5.7 | 8.1 | - | - | 2.3 | 3.2 | - | - |

3.1/2X1/2 | 101.6 | 21.3 | 203 | 5.7 | 8.1 | - | - | 2.8 | 3.7 | 4.8 | 7.5 |

3.1/2X3/4 | 101.6 | 26.7 | 203 | 5.7 | 8.1 | - | - | 2.9 | 3.9 | 5.6 | 7.8 |

3.1/2X1 | 101.6 | 33.4 | 203 | 5.7 | 8.1 | - | - | 3.4 | 4.5 | 6.4 | 9.1 |

3.1/2X1.1/4 | 101.6 | 42.2 | 203 | 5.7 | 8.1 | - | - | 3.6 | 4.9 | 6.4 | 9.7 |

3.1/2X1.1/2 | 101.6 | 48.3 | 203 | 5.7 | 8.1 | - | - | 3.7 | 5.1 | 7.1 | 10.2 |

3.1/2X2 | 101.6 | 60.3 | 203 | 5.7 | 8.1 | - | - | 3.9 | 5.5 | 8.7 | 11.1 |

3.1/2X2.1/2 | 101.6 | 73.0 | 203 | 5.7 | 8.1 | - | - | 5.2 | 7.0 | 9.5 | 14.0 |

3.1/2X3 | 101.6 | 88.9 | 203 | 5.7 | 8.1 | - | - | 5.5 | 7.6 | 11.1 | 15.2 |

4X1/4 | 114.3 | 13.7 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.2 | 3.0 | - | - |

4X3/8 | 114.3 | 17.1 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.3 | 3.2 | - | - |

4X1/2 | 114.3 | 21.3 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.8 | 3.7 | 4.8 | 7.5 |

4X3/4 | 114.3 | 26.7 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.9 | 3.9 | 5.6 | 7.8 |

4X1 | 114.3 | 33.4 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.4 | 4.5 | 6.4 | 9.1 |

4X1.1/4 | 114.3 | 42.2 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.6 | 4.9 | 6.4 | 9.7 |

4X1.1/2 | 114.3 | 48.3 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.7 | 5.1 | 7.1 | 10.2 |

4X2 | 114.3 | 60.3 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.9 | 5.5 | 8.7 | 11.1 |

4X2.1/2 | 114.3 | 73.0 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.2 | 7.0 | 9.5 | 14.0 |

4X3 | 114.3 | 88.9 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.5 | 7.6 | 11.1 | 15.2 |

4X3.1/2 | 114.3 | 101.6 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.7 | 8.1 | - | - |

Wall Thickness (T1,T2) in accordance with ASME B36.10M | ||

|

|

|

|

|

|

|

|

|

| DIMENSIONAL TOLERANCES OF SWAGED NIPPLES | |||||

| MSS SP-95-2014 | Unit:mm | ||||

| Mominal Pipe Size(Inch) | Overall Length | Outside Diameter at End | Fitting Wall Thickness (see Note 1) | ||

| Square Cut Ends | Other End Connections | ||||

| 1/8~3/8 | ±1.5 | +0.4 -0.8 | ±0.8 | Not less than 87.5% of Nominal Wall Thickness | |

| 1/2~1.1/2 | ±1.5 | +0.4 -0.8 | +1.5 -0.8 | ||

| 2~2.1/2 | ±3.0 | ±0.8 | +1.5 -0.8 | ||

| 3~4 | ±3.0 | ±0.8 | ±1.5 | ||

Note1:Prior to threading or grooving.